The "Aircraft Doctor" performs a four ton "Heart" surgery: over a hundred disassembly steps, with no difference in coordination

Lanzhou, October 19th (Xinhua) (Reporter Gao Ying) "A little bit outward", "Pay attention to balance, not yet in place", "Slow down, slow down".

Lanzhou, October 19th (Xinhua) (Reporter Gao Ying) "A little bit outward", "Pay attention to balance, not yet in place", "Slow down, slow down"... More than ten "airplane doctors" are performing surgery on a "heart" weighing up to four tons. How difficult is it?

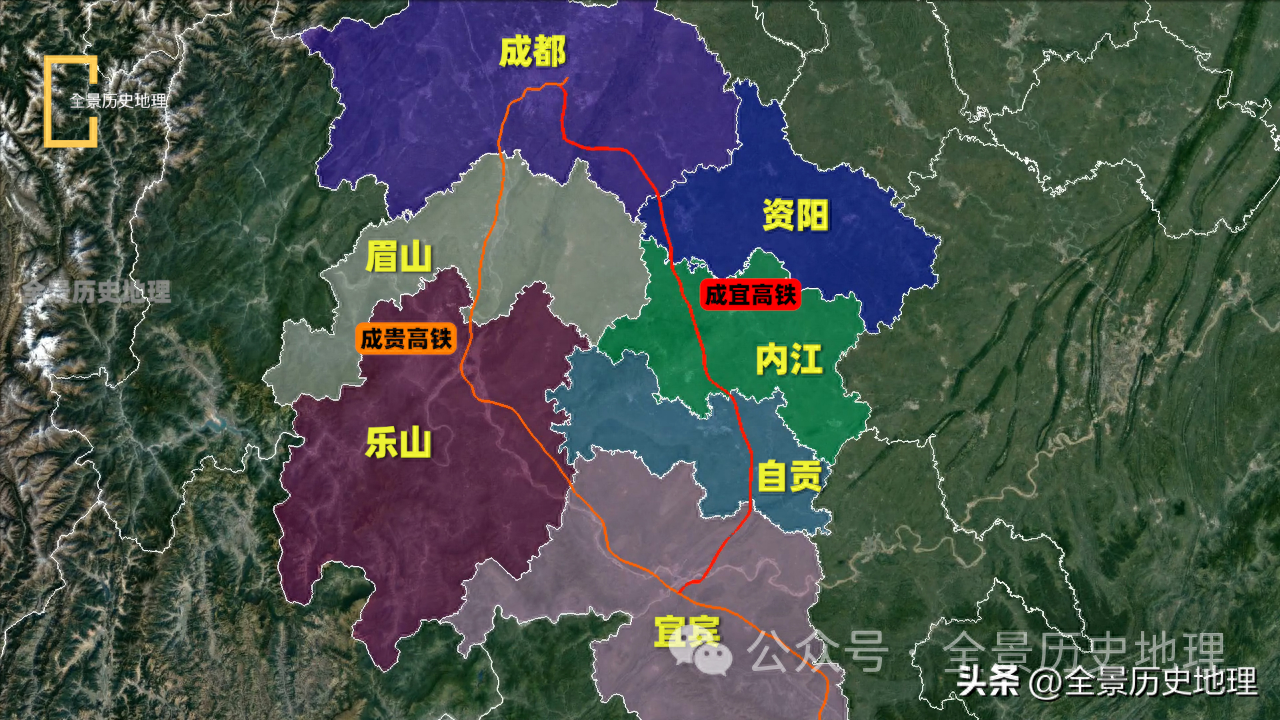

Aircraft maintenance personnel are also known as "aircraft doctors", who, like hospital doctors, are subdivided into many different "departments" based on the aircraft structure. The electronic group is referred to as a "neurologist", handling the brain and nerves of airplanes; The metalworking team, responsible for the structural safety of the entire aircraft, is known as the "orthopedic doctor"; There is also a painter group responsible for the appearance of the aircraft, known as the "beauty doctor" and so on. Different groups cooperate with each other to ensure safe flight.

On October 18th, the reporter visited the scheduled inspection hangar of China Eastern Airlines Gansu Branch located at Lanzhou Zhongchuan International Airport, and more than ten maintenance personnel gathered around an A320 aircraft that was about to undergo "heart surgery", making preparations.

Zhang Ning, the team leader of the scheduled inspection workshop of China Eastern Airlines Technology Gansu Branch, responsible for the overall scheduling of this "heart surgery", is one of the "surgeons" among the "aircraft doctors". This is not the first time he has been responsible for aircraft engine replacement work. Although he is familiar with the process, he still dare not be careless in the face of details.

Zhang Ning held a loudspeaker and kept surrounding the engine for inspection, sometimes squatting down to check the position, and sometimes coordinating with maintenance personnel at different positions to adjust the force. He introduced that this task is to replace the left engine of the aircraft. One engine weighs four tons and there are hundreds of disassembly steps in the work order.

The picture shows the maintenance personnel preparing for the aircraft's "heart" surgery. Photographed by Li Yalong

The engine is one of the most important components of the aircraft body, and replacing the engine requires the work of multiple aircraft systems. The dismantling and replacement of a large number of components is very difficult technically.

The engine dismantling team consists of about ten people. Firstly, the various points where the engine is connected to the aircraft need to be disconnected with tools. Then, the engine should be placed on a rack smoothly and finally pushed out. The entire dismantling process takes four to five hours. Zhang Ning said that the most important thing is the coordination between the maintenance personnel at each point, and it is necessary to maintain the balance of force when the engine descends, There should be no deviation in the strength of any corner, which greatly tests the collaborative ability and tacit understanding of "aircraft doctors".

The reporter saw on site that the space under the engine side fairing was narrow, and the "aircraft doctor" needed to climb onto a one meter high tripod and work under the cover, with the only light source being a overhead lamp. When doing homework, the space inside is relatively cramped and the light is very dim. It takes about four to five hours to drill inside, and there are many pipelines, so it's also quite difficult, "Zhang Ning said.

The "aircraft doctor" drilled into the engine for inspection work. Photographed by Li Yalong

Under what circumstances will aircraft engines undergo large-scale "heart surgery"?

Zhang Ning, holding a flashlight while inspecting, introduced to the reporter that there are two types of engine replacement: one is to return the engine to the factory for regular repair after a period of use, and the other is to have a malfunction and the engine can no longer run, so it needs to be disassembled and replaced directly. Normally, the engine is replaced every seven to eight years, and the removed engine will be sent to the engine manufacturer for comprehensive maintenance.

After five hours of homework, under the unified command, the aircraft engine slowly landed on the rack, and the "aircraft doctors" slowly pushed out the engine components and moved them to the nearby area. The 'big guy' weighing up to four tons requires a combination of seven or eight people to push it forward.

The picture shows the newly disassembled engine resting on a rack and slowly pushing out. Gaoying Photography

It is understood that maintenance work similar to aircraft engine "heart surgery" is almost conducted once a month. In order to ensure that the engine remains in good working condition, aircraft maintenance engineers also conduct regular maintenance of the engine at different depths. (End)

Source: China News Network

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.(Email:[email protected])