The 13 kilometer tunnel has been repaired for 14 years! How many Chinese engineers have turned their green hair into white hair as tunnels turn into water curtains

You may have heard of it,China has a tunnel with a total length of only 13.39 kilometers, but it took 14 years to complete,What's going on here?This tunnel is the Shanyang Tunnel of the Dali Ruili Railway,It is known as the most difficult railway tunnel for surrounding rock excavation in China, and sometimes even becomes a "water curtain tunnel",Causing headaches for engineers

You may have heard of it,China has a tunnel with a total length of only 13.39 kilometers, but it took 14 years to complete,What's going on here?

This tunnel is the Shanyang Tunnel of the Dali Ruili Railway,It is known as the most difficult railway tunnel for surrounding rock excavation in China, and sometimes even becomes a "water curtain tunnel",Causing headaches for engineers. What is the story behind this? Let's take a look together.

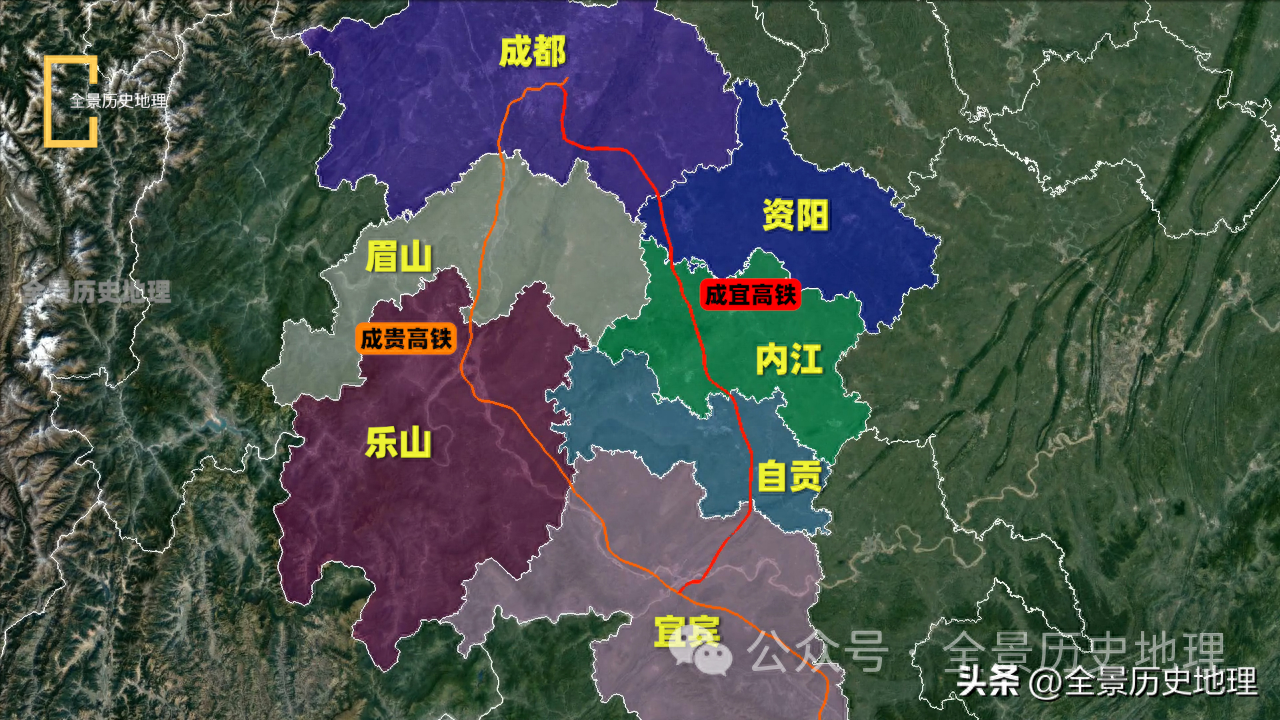

The Shanyang Tunnel is located at the junction of Dali Bai Autonomous Prefecture and Dehong Dai and Jingpo Autonomous Prefecture in Yunnan Province, and is an important component of the China Myanmar International Corridor. This tunnel started construction in 2007,It was not until March 28, 2021 that the connection was achieved, after 14 years of arduous excavation.

Why did it take so long? Originally, the geological conditions of this tunnel were extremely complex, just like a "geological museum".

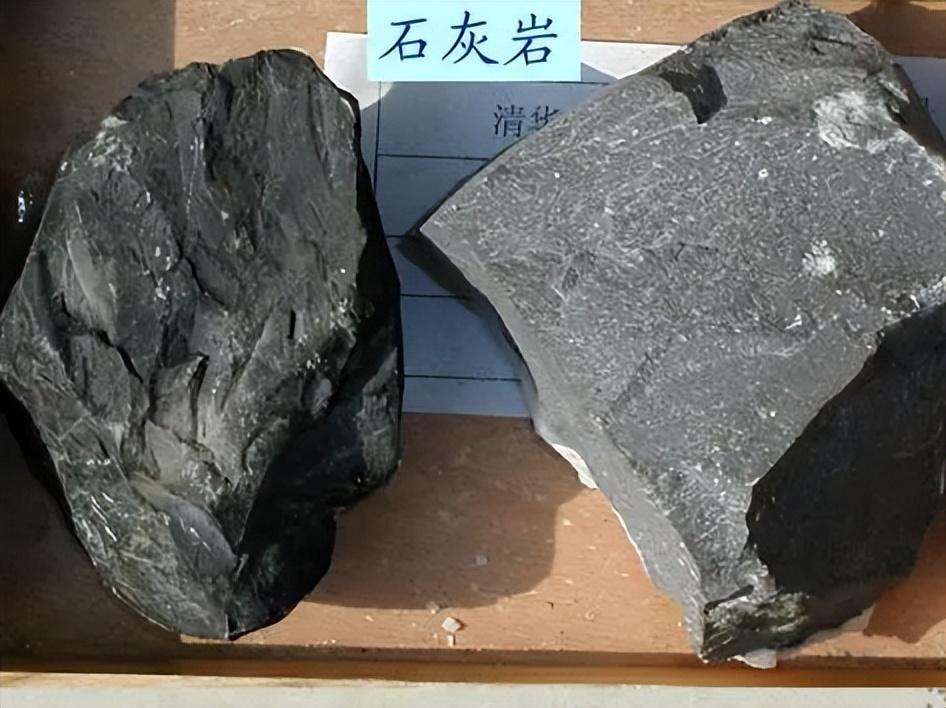

The Shanyang Tunnel has a total length of 13.39 kilometers and a maximum burial depth of 995 meters.At such a deep underground level, the tunnel passes through various strata and rocks, including sandstone, shale, limestone, gypsum salt rock, coal seams, goaf, and so on.

The physical and mechanical properties of these strata and rocks are different, some are soft, some are hard, some are dry, some are wet, and some are stable and some are dynamic. This poses a huge challenge to tunnel construction.

1. Problem 1: Water Curtain Cave

One of the biggest challenges during the construction of the Shanyang Tunnel is water gushing. Due to the location of the tunnel in the karst landform area, groundwater resources are very abundant. Moreover, due to reasons such as fractured strata, developed cracks, and numerous goafs, groundwater is easily flowing into the tunnel from all directions.Especially during the rainy season and the melting of ice and snow, the water inflow increases even more sharply.

It is reported that there have been multiple water inrush accidents during the construction of the Shanyang Tunnel.The most serious incident occurred on June 30, 2015, only 300 meters away from the exit.

At that time, during the flood season, a water column with a diameter of about 1 meter suddenly emerged from the ceiling, flooding the entire entrance. The water column is about 10 meters high, forming a spectacular 'Water Curtain Cave'.The workers had to evacuate urgently and block the entrance with sandbags.

Faced with the problem of water inrush, engineers have taken various measures to address it. Firstly, a detailed geological survey and prediction should be conducted before excavation,Identify potential locations with water inrush risks and take preventive measures in advance.

Secondly, grouting reinforcement and drainage treatment should be carried out in a timely manner during the excavation process to prevent water inrush from causing damage and collapse of the surrounding rock. Finally,A dedicated drainage system should be set up inside the tunnel to discharge excess water,Keep the interior of the tunnel dry and safe.

2. Problem 2: High temperature and high pressure

In addition to water inrush, the construction process of the Shanyang Tunnel also faces the problem of high temperature and pressure. Due to the deep burial depth of the tunnel and the high underground temperature,Combined with the operation of mechanical equipment and personnel operations, the temperature inside the tunnel can easily rise.

According to measurements, the highest temperature inside the tunnel has reached over 40 degrees Celsius, accompanied by high humidity and low oxygen.This environment is a test for both the physical and mental health of workers.

In order to reduce the temperature inside the tunnel, engineers have adopted various methods. Install a ventilation system inside the tunnel to deliver fresh air to the interior and exhaust hot air from the tunnel. The second is to install a cooling system at the entrance of the tunnel,Use ice or cold water to cool the air entering the tunnel.

Sunshade or spray equipment is also set inside the tunnel to reduce direct sunlight and evaporative heat dissipation.The fourth is to set up rest rooms or medical rooms inside the tunnel to provide necessary rest and assistance for workers.

3. Problem 3: Rock burst gas

During the construction of the Shanyang Tunnel, problems such as rock burst and gas were also encountered. Rock burst refers to the process of excavation,A sudden rupture phenomenon that occurs due to stress release or sudden deformation of the surrounding rock.

Rock burst can cause the surrounding rock to splash or collapse, posing a hazard to personnel and equipment. Gas refers to the presence of combustible gases such as methane, carbon monoxide, etc. underground.Gas can cause air pollution or explosions, posing a hazard to personnel and equipment.

In order to prevent the occurrence of rock bursts and gas, engineers have adopted various methods. The first step is to conduct stress measurement and gas detection before excavation, evaluate the risk level of rock burst and gas, and develop corresponding preventive measures. Reasonable excavation methods and parameters should be used during the excavation process,Avoid excessive stress concentration or sudden changes, and promptly carry out surrounding rock support and reinforcement.

During the excavation process, regular monitoring and early warning should be carried out to promptly detect abnormal situations and take emergency measures.The fourth is to strengthen the ventilation and emission system during the excavation process to ensure air quality and safety.

summary

The Shanyang Tunnel is a challenging and miraculous tunnel that has undergone 14 years of arduous excavation,Overcoming various difficulties such as water inrush, high temperature, rock burst, gas, etc., and ultimately achieving connectivity.Behind this lies the wisdom and sweat of many Chinese engineers, and how many Chinese engineers have turned their hair white.

This tunnel is not only a great engineering achievement, but also an invaluable spiritual asset. It showcases the wisdom and courage of Chinese engineers, as well as the struggle and innovation of the Chinese people.

What do you think of this? Let's discuss it together in the comment section!

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.(Email:[email protected])