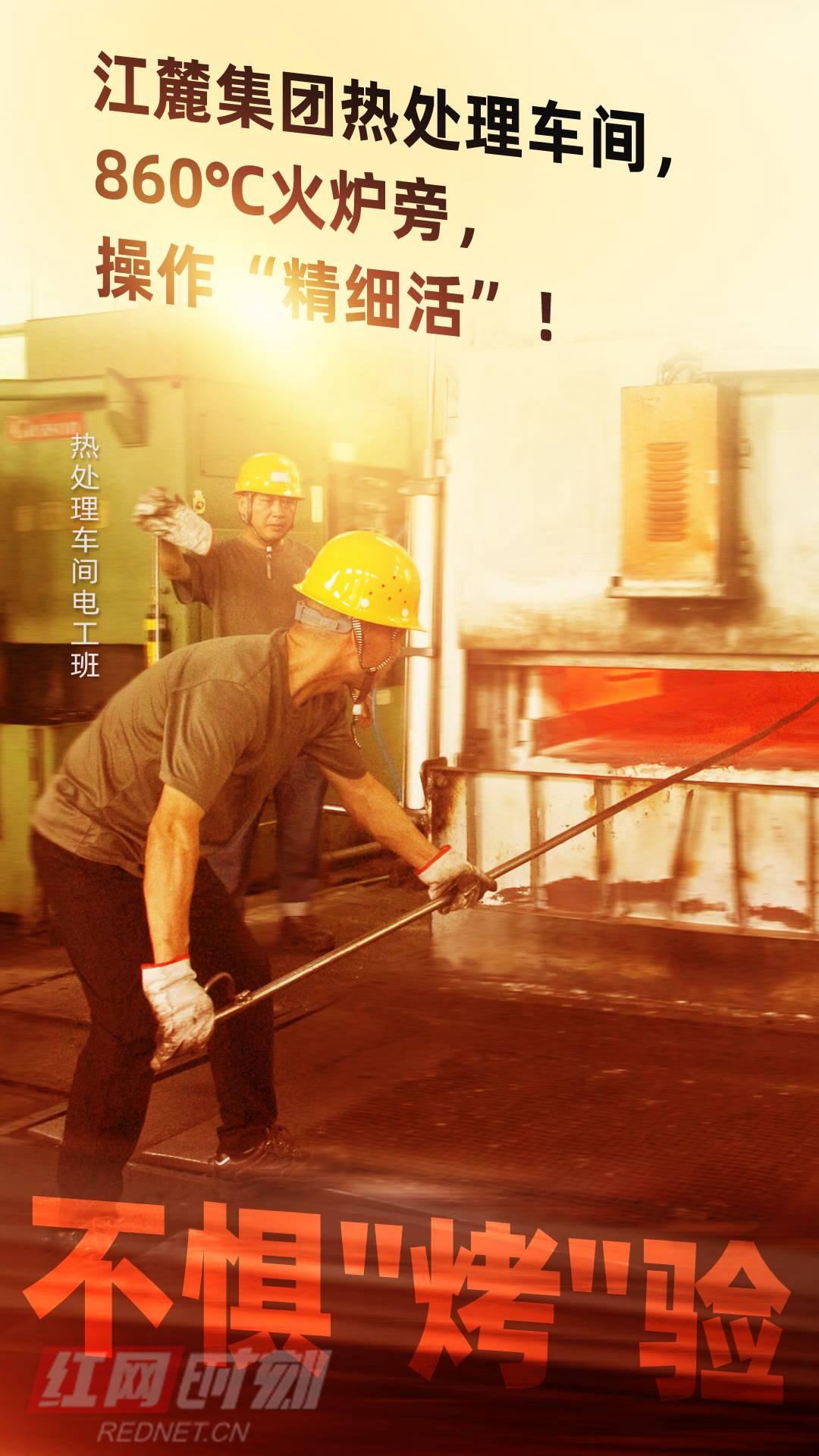

Fearless of "Roasting" Inspection | Jianglu Group Heat Treatment Worker: 860 High Temperature Side Operation "Fine Work"

Red Net Moment News Reporter Ling Yuqing Intern Huang Yiyuan Correspondent Wang Zefen Reports from Xiangtan30 quenching furnaces are in operation in the heat treatment workshop of Jianglu Group.As soon as I entered the workshop, a heatwave swept over my face, and 30 quenching furnaces were working

Red Net Moment News Reporter Ling Yuqing Intern Huang Yiyuan Correspondent Wang Zefen Reports from Xiangtan

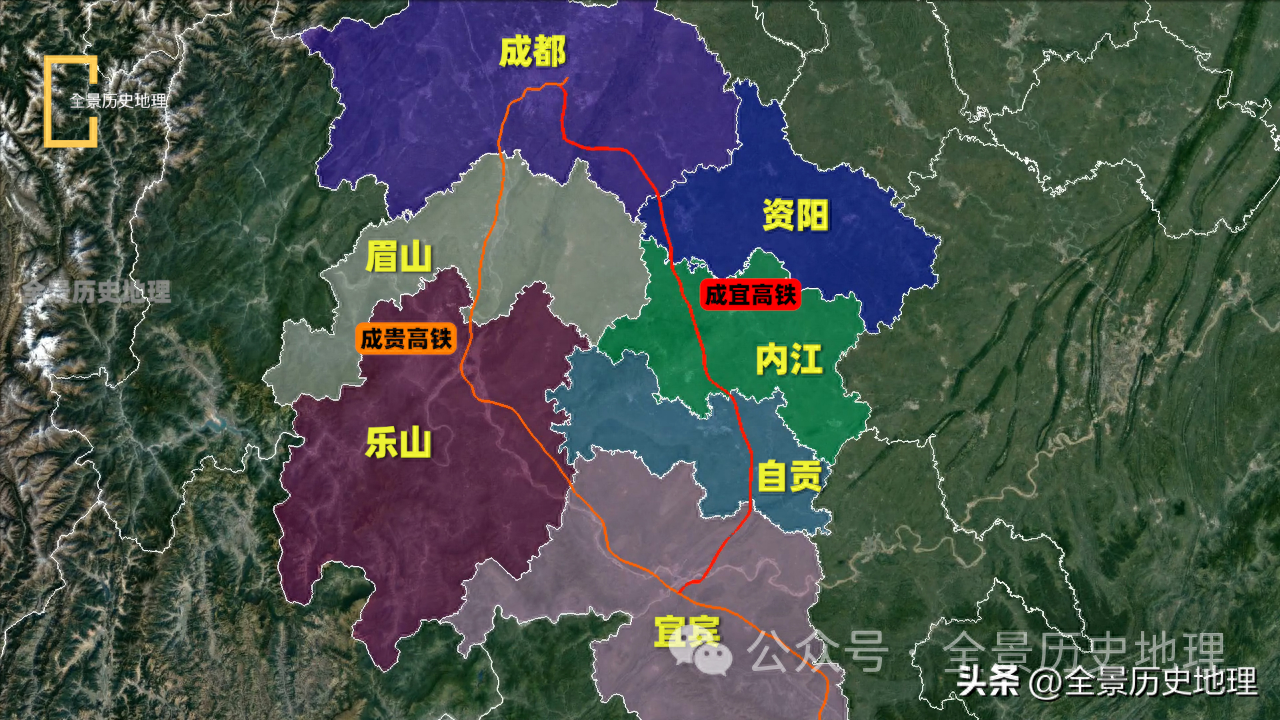

30 quenching furnaces are in operation in the heat treatment workshop of Jianglu Group.

As soon as I entered the workshop, a heatwave swept over my face, and 30 quenching furnaces were working. The high temperature filled every corner of the workshop, and the air was stuffy and dry.

As the stove gradually opened, a scorching heat wave surged out.

The workers need to use a long hook to hang the product on the crane chain.

It's coming out immediately, everyone. "At 9 o'clock in the morning, the first batch of products is ready to be released. I saw Liang Jian, the electrician class leader of the heat treatment workshop, wearing cotton gloves and holding a long iron hook about a foot away from the furnace door, waiting for the product to be released from the furnace.

As the furnace door opened little by little, a scorching heat wave surged out, and the pores of the whole body instantly opened, causing beads of sweat to flow down the forehead unconsciously. Liang Jian skillfully hooked out the product parts one by one with a hook, water quenching, oil quenching, air cooling... everyone's face was flushed with the furnace light.

The products after being fired are undergoing oil quenching, and the fire has turned everyone's face red.

Rapid cooling further enhances the hardness of the product.

Since summer arrived, our class has advanced the working hours by one hour and started the furnace at the work site at 6 am, so it won't be too hot. "Liang Jian said that after starting work, the entire workshop will reach around 40 degrees Celsius, and the closer it is to the furnace, the hotter it will become. By the afternoon, it can even reach around 50 degrees Celsius.

In a moment, the worker's clothes were soaked with sweat.

Heat treatment is an important production process in product manufacturing, and every step should be error free. Among them, process control is the most crucial, requiring the control of heat treatment equipment and various temperature parameters, insulation time, and cooling methods, all of which are key to ensuring product quality.

"Many important equipment components and products must undergo Hot working and quenching to ensure their quality. We stood by and stared at them with confidence." Liang Jian told us that the staff lounge with air conditioners was one aisle away from the workshop, but few people stayed. It was not because everyone didn't want to feel cool and comfortable here, but because of their sense of responsibility.

Taking advantage of the gap, Liang Jian hurriedly went to the lounge to have a drink of water, and soon returned to the next round of work.

Although working hard in the heat wave every day, the members of the electrician team are very proud because the heat treatment workshop can handle over 50000 tons of products annually. They make important parts of the company's military products, and all production work is completed on time with quality and quantity guaranteed. As a result, the team has also won numerous honors and awards such as the "Red Flag Model Team".

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.(Email:[email protected])