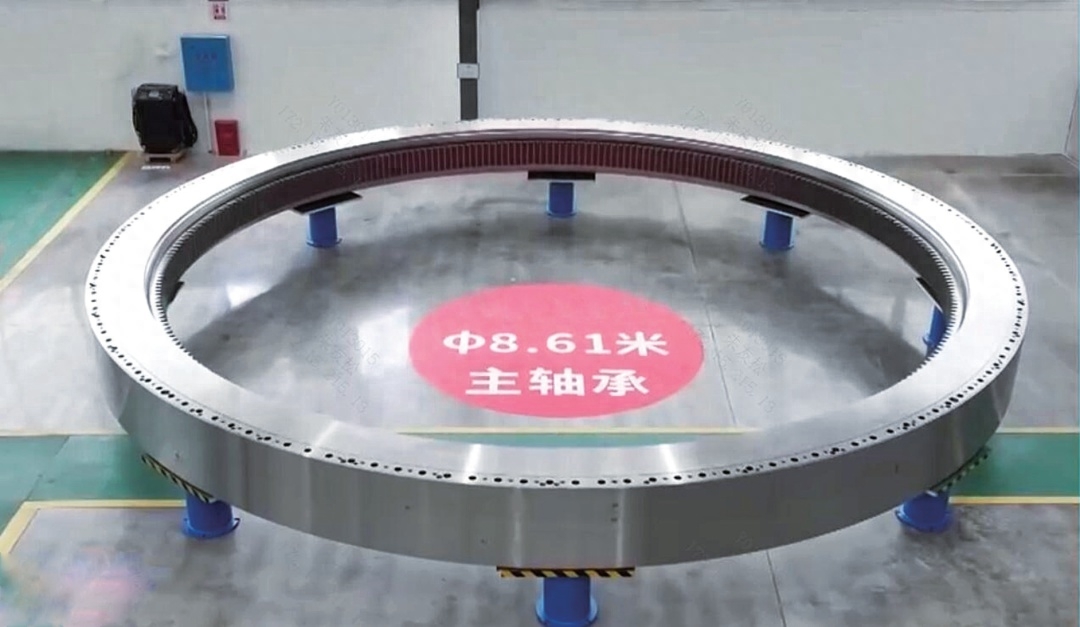

Bull! Daye Special Steel Manufacturing Set a World Record

12thManufactured with special steel materials developed by Daye Special SteelMain bearing of shield tunneling machine with a diameter of 8.61 metersOffline in ChangshaMain bearing of shield tunneling machine with a diameter of 8

12th

Manufactured with special steel materials developed by Daye Special Steel

Main bearing of shield tunneling machine with a diameter of 8.61 meters

Offline in Changsha

Main bearing of shield tunneling machine with a diameter of 8.61 meters

This is the largest diameter in the world to date

The heaviest and most load-bearing individual

Main bearing of integrated shield tunneling machine

Its successful development

Marked the development of domestically produced super large diameter main bearings

And its industrialization ability has reached the world's leading level

Means

The main bearings of shield tunneling machines have achieved comprehensive localization

Daye Special Steel has successfully developed a single weight of 65 tons of bearing steel mold cast steel ingots.

Successively becoming the first domestically produced 11 meter level machine

After providing materials for the main bearings of the 16 meter shield tunneling machine

Daye Special Steel and User Cooperation

Develop shield tunneling machines with a height of over 18 meters for it

High quality and long life bearing steel for main bearings

In the process of developing the main bearing material for the 8.61 meter shield tunneling machine, in order to ensure that the bearing steel meets extremely strict and ultra-high performance requirements in large size, high tonnage, and large cross-section, Daye Special Steel technicians have repeatedly used software simulation technology to reasonably design product drawings, produced a 68 ton steel ingot mold, and carefully studied the optimal pouring process parameters and annealing process to overcome on-site difficulties. They have carefully organized trial production and production, Successfully developed a 65 ton die cast steel ingot for the first time, and also developed and provided supporting electroslag spheroidized annealing materials for large-sized 140mm rolling elements. After being manufactured and processed by users, this 8.61 meter diameter main bearing weighs 62 tons per unit and can be used to drive an 18 meter ultra large diameter shield machine, capable of withstanding loads of over 10000 tons.

As the "heart" component of the shield tunneling machine, the main bearing needs to face the extreme harsh working conditions of the machine, such as overload, large eccentric load, and frequency variable load. Its service life and reliability are constrained by various key factors such as materials, design, manufacturing, and testing, and the difficulty of development doubles with the increase of size. Previously, the key technology of the main bearings of ultra large diameter shield tunneling machines had been monopolized by foreign enterprises for a long time, and was listed as a "bottleneck" key technology that restricts China's industrial development. It is the "last link" of the full industry chain autonomy of shield tunneling machines.

at present

From small to large diameters

Daye Special Steel has achieved

Development of materials for main bearings of domestic shield tunneling machines

Full coverage

(Source: Published by Huangshi)

Editor: Zhang Jing

[Source: Huangshi Release]

Disclaimer: The content of this article is sourced from the internet. The copyright of the text, images, and other materials belongs to the original author. The platform reprints the materials for the purpose of conveying more information. The content of the article is for reference and learning only, and should not be used for commercial purposes. If it infringes on your legitimate rights and interests, please contact us promptly and we will handle it as soon as possible! We respect copyright and are committed to protecting it. Thank you for sharing.(Email:[email protected])